Solution

Advantages of LEWA packages for the injection of demulsifiers:

- High metering accuracy

- Leak-free, hermetically tight

- Very good suction capability of the spring-loaded diaphragm return M900 pump head

- Easy diaphragm replacement

- All movable parts operate in protective and lubricating hydraulic fluid

- Compact, modular design, which allows installation in the available space (e.g. on FPSOs)

- Long service life (often more than 10,000 hours of continuous operation)

- Avoidance of expensive production interruptions by using a sandwich diaphragm: Operation can be continued until the service team is on-site and the repair fits into the work flow

Background

Process description

Demulsifiers are compounds that dispersed in very small amounts into the emulsion during injection that diffuse into the oil-water interface and function as stabilizers. They have a multitude of action mechanisms:

- Reduction or prevention of electrostatic charges, which are responsible for the repulsion between the individual drops

- Change of the wettability of the solids absorbed in the interface

- Change of the viscoelasticity of the interface film

Description of the demulsification process:

The demulsifier concentrates on the surface of the small water drops and "collects" them. The drops form an increasing concentration of water. The water drops which refract the light, are removed. The visible effect is the brightening of the oil layer. The water droplets finally combine and are separated.

Why is the demulsifier a mixture?

Demulsifiers normally offer a combination of effects as:

- Flocculent

- Droplet separator

- Wetting agents

A single substance cannot offer these combined properties, thus commercial demulsifier mixtures consist of several substances.

The most widely used methods are demulsifier injection systems at the bore hole and at collection points.

Bore hole injection is recommended:

- The pumps used there are smaller and therefore less expensive.

- The earlier in the process the water is removed, the less corrosion occurs (lower maintenance costs)

Considerable cost reduction due to demulsifying crude oil:

- Easier transport and lower pressure loss due to viscosity reduction

- Simple steel alloys can be used for pipelines and fittings instead of corrosion-resistant stainless steel, and in addition the cross-section can be reduced.

- The corrosive portions in the crude oil are minimized and reduce corrosion in the production equipment

- Longer operating times are possible

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsProducts

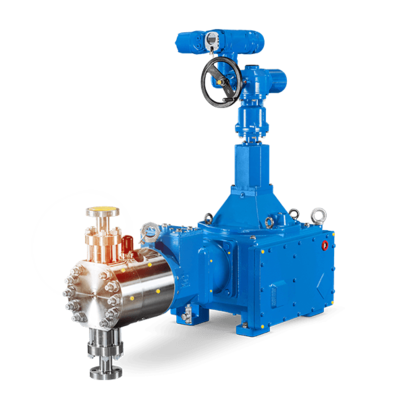

LEWA ecosmart® diaphragm metering pump

LEWA ecosmart is an innovative, compact and multiplexing diaphragm metering pump at a smart price. With it, we of course guarantee our renowned LEWA quality and offer you our expertise derived from 70 years in the market.

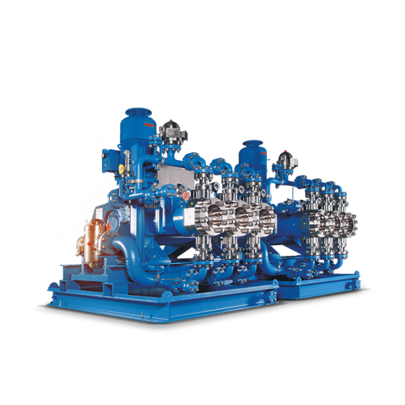

More DetailsLEWA ecoflow® process pumps for high-pressure applications

The innovative ecoflow diaphragm process pump shows its strengths in high-pressure applications in the oil and gas, refinery and petrochemical industries as well as in the sensitive areas of pharmaceuticals, biotechnology, food and beverage production.

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA Flow Distribution Systems (FDS)

With the help of LEWA Flow Distribution Systems and several Injection Rate Control Devices (IRCDs), a fluid can be metered to the process at several points.

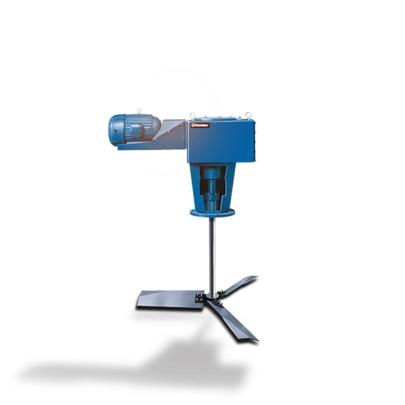

More DetailsChemineer Mixing technology

Chemineer agitators cover a wide range of products. From turbine agitators to impellers, these agitators can be used in almost any process that requires liquid or gas agitation.

More Details