Oil and gas industries

Used offshore and onshore all over the world

Customers across the globe put their trust in our products in the oil and gas production industry. From antifouling agents through to wax inhibitors – with our pumps and custom packages, you know you are using chemicals safely.

Of course, our pumps also meter corrosion inhibitors, oxygen binders, and other toxic and corrosive substances without a problem and guarantee absolute process safety.

What is more, LEWA offers reliable solutions for high-pressure injection and sealless crude oil and natural gas production. Our systems can cope with the harshest environments: Whether in cold Siberia, the hot Arabian Desert, or on the rough sea – with LEWA products, you're guaranteed efficient and fail-safe processes.

Areas of Application in the Oil & Gas Industry

Whether for the conveyance or further treatment of raw materials – LEWA products and systems offer solutions for all processes in oil and gas production.

| Product applications | Chemicals | Purpose |

|---|---|---|

| Treating oil, gas, and water | Foam inhibitors | Reduce foam to ensure maximum flow rate |

| Asphalt inhibitors, antifouling agents | Prevent asphalt formation | |

| Biocides | Minimize the growth of aerobic and anaerobic bacteria | |

| Calcium nitrates | Prevent the formation of dissolved sulfides and H2S | |

| Corrosion inhibitors | Reduce corrosion in pipelines | |

| Demulsifiers, emulsion breakers | Split stable oil-water emulsions | |

| Oil separators/flocculants | Separate oil and production water | |

| Friction reducers, flow rate improvers | Reduce friction losses in pipelines | |

| H2S binders | Prevent corrosion by hydrogen sulfide | |

| Hypochlorites | Prevent the growth of organisms | |

| Hydrate inhibitors with low density/LDHI | Hydrate inhibitors with low metering rate | |

| Oxygen binders | Remove residual oxygen | |

| Paraffin inhibitors | Prevent paraffin formation | |

| PH control agents | Reduce glycol decomposition | |

| Polyelectrolytes | Filter aids | |

| Crust inhibitors, crust reducers | Prevent process equipment crusting | |

| Clarifiers for water | Remove oil particles in production water | |

| Wax inhibitors | Prevent wax formation | |

| Solar-powered systems for injecting chemicals | Corrosion inhibitors, methanol | Inject chemicals in remote and unmanned production sites or pipelines |

| Gas-powered systems for injecting chemicals | Corrosion inhibitors, methanol | Inject chemicals without emitting (acid) gas in remote or unmanned production sites or pipelines |

| High-pressure injection | Carbon dioxide CO2 | Injection underground |

| Hydrogen sulfide H2S | Injection underground | |

| Methanol/ethanol | Prevents the formation of hydrate in gas production sites | |

| Glycol (MEG/TEG) | Gas dehydration | |

| Sealless conveying | Condensate | Leak-free pumping of separated product with low feed pressure (high vapor pressure) |

Solutions for the Oil & Gas Industry

Count on an experienced supplier – LEWA! Our qualified equipment for natural gas production allows us to comply with all requirements in the oil and gas industry. We offer EPC companies, operators, and end customers our complete portfolio of high-end diaphragm and plunger pumps.

When developing pumps for extracting crude oil and natural gas, we take industry standards as well as your requirements and circumstances into consideration. High pressures, hermetically sealed units, and extreme safety in a compact design are a matter of course for LEWA. We offer you a safe tool for natural gas production in the form of our pump head, for example, which features a PTFE diaphragm for pressures up to 1000 bar and ensures maximum cost-efficiency!

Our many years of experience mean that we are able to offer international engineering and project expertise to assist you in all phases of your project.

Advantages at a Glance

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

International standards

LEWA is ISO 9001 certified. Pumps, systems and units are compliant with all major international standards such as, API, ASME, TÜV and many more.

Calculation of fluid dynamics

When designing pumps and systems, we rely on computer-based calculations of the fluid dynamics in the pipelines and on appropriate integration of pulsation dampers.

Tests according to your specifications

Before starting up the system, we conduct well-documented test runs according to relevant international standards or to your specifications.

Flexible design

You can rely on over 60 years of experience in the design of pumps, systems and units: During the project phase, we respond flexibly to design changes or adjustments required.

Spare parts information in your language

You will get all available information about spare parts (including subcontractors) in your preferred language. Our spare parts service functions quickly and smoothly.

Certified welders

Highest quality and professionally trained staff: Welding jobs are performed by certified welders. On request, we install your system directly at your site.

Applications

Injection of corrosion inhibitor

Do you require systems for the injection of corrosion inhibitor? At LEWA, you can find expert consultation, detailed information and support!

More DetailsMethanol injection

Use skids and packages by LEWA for methanol injection in the oil and gas industry. Ask our experts for more information!

More DetailsCCS carbon capture and storage

Use LEWA process pumps for CCS (carbon capture & storage) processes and carry out the CO2 separation efficiently. We are happy to help.

More DetailsDisposal of hydrocarbon condensate

LEWA systems help you transport and dispose of hydrocarbon condensates (HCC) that arise when producing natural gas, both onshore and offshore.

More DetailsGas drying with glycol

LEWA provides reliable injection pumps and systems for gas drying with glycol. Ask our experts for more information today.

More DetailsInjection of demulsifiers

Injection of demulsifiers with LEWA packages in the oil and gas industry. We provide you with advice tailored to your application.

More DetailsSolar pump for onshore production

For more than 30 years LEWA has been providing autonomous chemical injection systems with solar-powered metering pumps.

More DetailsPigging technology and pig cleaning

LEWA offers packages for pigging applications in oil and gas industry. These packages are designed according to customers‘ requirements and are also available in explosion-proof design.

More DetailsProcessing of produced water

Produced water packages from LEWA can be used to purify produced water during oil drilling. They are hermetically sealed and have options for exact control.

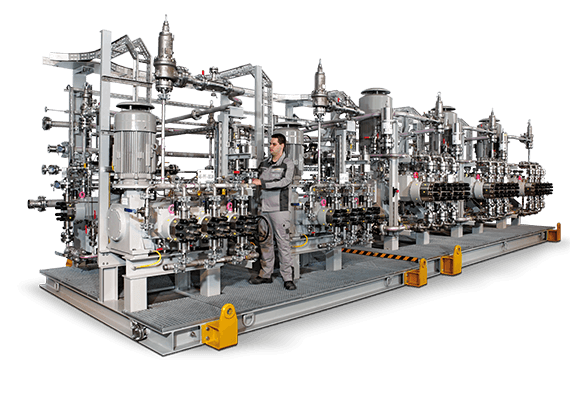

More DetailsLEWA’s biggest Chemical Injection Package

LEWA's biggest Chemical Injection Package includes 40 diaphragm pumps and has an estimated weight of 715 tons. Find out more about the record project!

More DetailsLPG fuel pumps for marine engines

LEWA triplex process diaphragm pumps offer many advantages as fuel pumps for LPG in marine engines.

More DetailsProducts

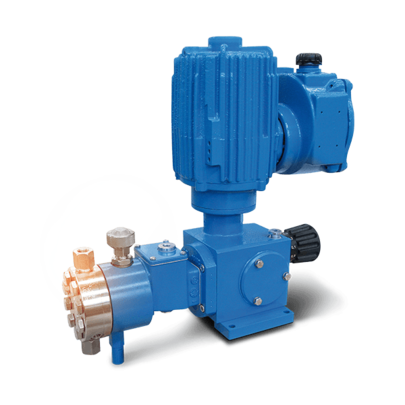

LEWA ecoflow® diaphragm metering pump

LEWA ecoflow is the innovative and universal metering pump with DPS diaphragm protection system in a tried-and-tested modular system. Suitable for numerous applications, the ecoflow is our real all-around talent, relied on by customers from all industries.

More DetailsLEWA ecoflow ® packed plunger metering pump

The LEWA ecoflow packed plunger metering pump is the robust, tried-and-tested metering pump for unproblematic fluids. It is available in a wide variety of models and used by well-known customers for various processes.

More DetailsLEWA ecosmart® diaphragm metering pump

LEWA ecosmart is an innovative, compact and multiplexing diaphragm metering pump at a smart price. With it, we of course guarantee our renowned LEWA quality and offer you our expertise derived from 70 years in the market.

More DetailsLEWA MAH, MBH, MLM Micro-metering pumps

Metering pumps for very small flow rates. An especially cost-effective solution when fluid components must be metered proportionally to a variable reference value.

More DetailsLEWA FC laboratory pumps

Metering pumps for very small flow rates. The FC micro-metering pumps for pressures up to 400 bar were developed specifically for laboratories and test centers.

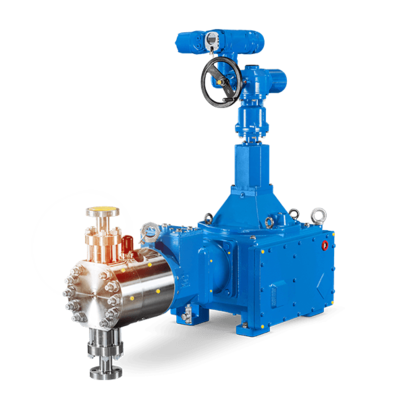

More DetailsLEWA ecoflow® process pumps for high-pressure applications

The innovative ecoflow diaphragm process pump shows its strengths in high-pressure applications in the oil and gas, refinery and petrochemical industries as well as in the sensitive areas of pharmaceuticals, biotechnology, food and beverage production.

More DetailsLEWA triplex® process pumps for high-pressure processes

The LEWA triplex process diaphragm pump is among the world's most compact high-pressure pumps and can even be set up in the tightest spaces when space is at a premium. The power package has proven its strength in numerous high-pressure processes in a variety of industries. Oil and Gas icon Gas odor icon gray Refinery icon Petrochemicals icon Chemicals icon Plastics icon gray Cleaning icon Cosmetics icon Pharma icon Food icon Energy icon Other icon

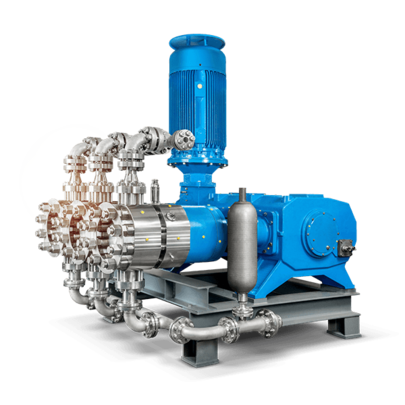

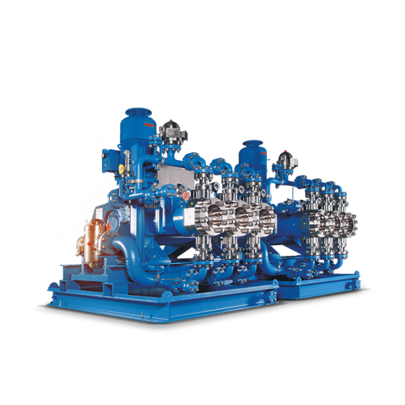

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

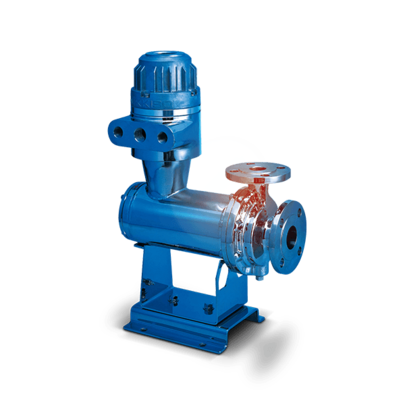

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA Flow Distribution Systems (FDS)

With the help of LEWA Flow Distribution Systems and several Injection Rate Control Devices (IRCDs), a fluid can be metered to the process at several points.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

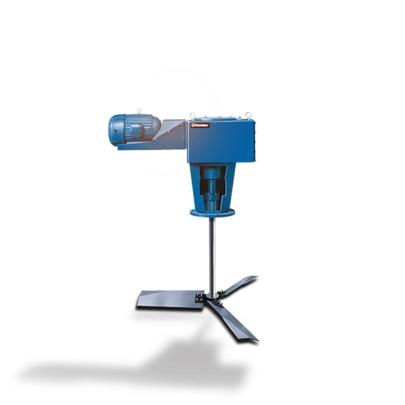

More DetailsChemineer Mixing technology

Chemineer agitators cover a wide range of products. From turbine agitators to impellers, these agitators can be used in almost any process that requires liquid or gas agitation.

More Details