Solutions for methanol injection with packages by LEWA

Advantages of LEWA packages for methanol injection:

- Reliable and leak-free for pressures up to 1,200 bar

- Very good suction capability of the spring-loaded diaphragm return M900 pump head

- Long service life of diaphragms (proven 10,000 hours and more)

- Reliable, fast diaphragm monitoring system for maximum process reliability in extreme pressure ranges

- Simple and swift diaphragm replacement

- All movable parts of the pump head are protected in an oil bath

- Special LEWA design easily overcomes high suction pressures and shut downs at high discharge pressures

- Extremely low maintenance requirements and reliable monitoring, therefore it is:

- Suited for both manned and unmanned operation

- Designed for continuous as well as intermittent operation in low/medium and high pressure injection applications

- Avoiding expensive production interruptions by using a sandwich diaphragm: The pump does not have be shut down immediately; operation can be continued until the maintenance team is on-site or the repair fits into the work flow

Other advantages

- Compact, modular design, allows installation in space available (e.g. on FPSOs)

- Flow rates from several hundred (continuous injection) up to several thousand liters per hour (intermittent metering) possible

- Precise phase-shifted multiple pumps make a low-pulsation and uniform metering possible even without a pulsation damper

- No separate lubeoil pumps with control and monitoring instruments are needed, since the crankcase has immersion lubrication and splah lubrication

Background for methanol injection

Methanol is a by-product of refining processes.

Properties of methanol:

Methanol is highly flammable and burns with a bright flame. It is barely visible in daylight, making it extremely dangerous. Flammable gas/air mixtures can form, and electrostatic combustion is possible (even at concentrations as low as 25%) Its decomposition products are carbon dioxide, carbon monoxide and formaldehyde.

Methanol itself is not toxic, but the enzymes that capture it in the human body form formaldehyde and formic acid. These products are highly reactive (formaldehyde) or extremely acidic (formic acid). Its reaction time in the body is 15 hours or more, so the actual cause of the poisoning often can no longer be determined. Methanol must therefore be handled with extreme caution and processed as leak-tight and leak-free as possible.

Use of LDHI:

In rare cases a methanol substitute is used, so-called LDHIs (Low Dosage Hydrate Inhibitors). This is the case when the later refining process does not tolerate methanol, since the last water preparation step is carried out biologically. The microbes that are used for the final removal of oil residues are killed by methanol. Since LDHIs are more expensive than methanol, they are only used if actually specified.

During use it must be taken into account that LDHI injection quantities are significantly lower, normally only 1/10 or 1/20 the quantity of the methanol. In addition, at high pressures (>350 bar) they can crystallize and become very abrasive and, for example, require the use of tungsten carbide valves.

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsProducts

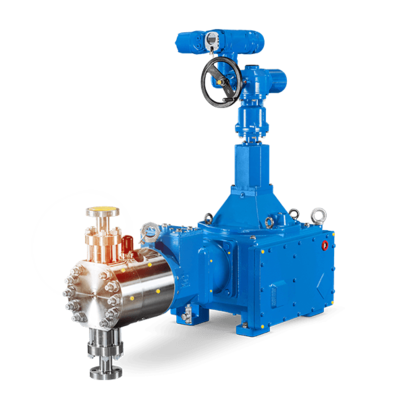

LEWA ecosmart® diaphragm metering pump

LEWA ecosmart is an innovative, compact and multiplexing diaphragm metering pump at a smart price. With it, we of course guarantee our renowned LEWA quality and offer you our expertise derived from 70 years in the market.

More DetailsLEWA ecoflow® process pumps for high-pressure applications

The innovative ecoflow diaphragm process pump shows its strengths in high-pressure applications in the oil and gas, refinery and petrochemical industries as well as in the sensitive areas of pharmaceuticals, biotechnology, food and beverage production.

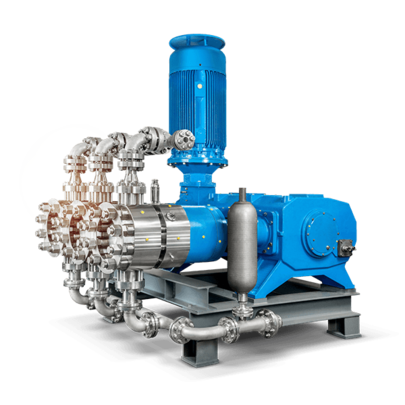

More DetailsLEWA triplex® process pumps for high-pressure processes

The LEWA triplex process diaphragm pump is among the world's most compact high-pressure pumps and can even be set up in the tightest spaces when space is at a premium. The power package has proven its strength in numerous high-pressure processes in a variety of industries. Oil and Gas icon Gas odor icon gray Refinery icon Petrochemicals icon Chemicals icon Plastics icon gray Cleaning icon Cosmetics icon Pharma icon Food icon Energy icon Other icon

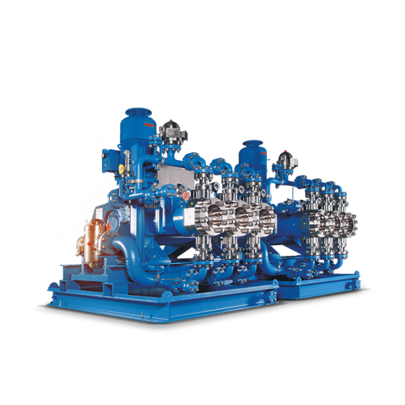

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA Flow Distribution Systems (FDS)

With the help of LEWA Flow Distribution Systems and several Injection Rate Control Devices (IRCDs), a fluid can be metered to the process at several points.

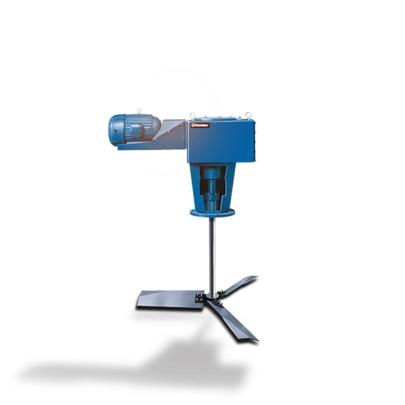

More DetailsChemineer Mixing technology

Chemineer agitators cover a wide range of products. From turbine agitators to impellers, these agitators can be used in almost any process that requires liquid or gas agitation.

More Details