LEWA odorizing systems

Safe gas odorizing in accordance with global regulations.

Odorizing gases is a complex task. The global regulations governing this application are strict and not always clear: In the past, gas suppliers relied on wick odorization, by-pass odorization, or simply adding odorants with no means of control. Today, this is prohibited in virtually every country – odorization must be monitored and performed proportionally and continuously.

LEWA has the expertise that comes with 40 years of experience and the necessary equipment to create your safe and regulation-compliant odorizing system. We adapt our systems to conform with country-specific standards and requirements. Whether odorization is decentralized or – as is the case in France, for example – takes place at a central location.

With LEWA odorizing systems you're placing your trust in the expertise of the market leader for efficient and safe gas odorization.

Good reasons to choose a LEWA odorizing system

A LEWA odorizing system is a quantity-dependent, gas flow-controlled system with closed loop control and a design that complies with applicable guidelines (including the German Federal Water Act (WHG), German Technical and Scientific Association for Gas and Water (DVGW), ATEX, GOST-R, ASME, Pressure Equipment Directive, German Technical Instructions on Air Quality Control (TA-Luft), and German Technical Regulations for Combustible Liquids (TRbF)).

Freely configurable standard components

Each LEWA odorizing system consists of standard components such as the control system, pump, vessel, trough, flow meter, lines & valves, and accessories. These components can be configured on a custom basis and in complete accordance with your requirements.

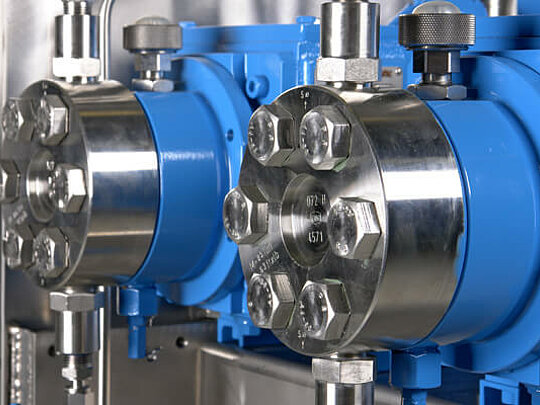

Reliable and approved components

Our odorizing systems use only tried-and-tested and approved components, while our diaphragm pumps are completely sealed and offer full reliability during metering. Control elements are also available in an Ex-protected design. We also supply magnetic, pneumatic or electrically powered pumps on request.

Odorizing various gases

With LEWA odorizing systems, you can add a special odorant to various gases: natural gas, biogas, LPG, oxygen, nitrogen, carbon dioxide, hydrogen, methane, and many more besides.

Suitable for all odorants

LEWA odorizing systems are suitable for all odorants. For many years now, our systems have been metering EM, DMS, TBM, THT, and sulfur-free substances for numerous customers with reliability and the utmost precision.

Maximum metering accuracy

The process of odorizing gases is dependent on exact metering accuracy. LEWA odorizing systems achieve a precision level of ±1%.

Precision flow meter

The LEWA KMM 1 flow meter is unique on the market and is able to measure even the lowest volume flows with absolute precision.

Integrated fill level control

The vessels are fitted with a visual fill level control which can be used while the pumps are being calibrated.

Diffusion-resistant metal diaphragm

The metal pump diaphragms are completely diffusion-proof and fail-safe.

Spare parts and service

Thanks to our network of global branch offices and sales partners, you'll get the best service and spare parts for your odorizing systems as quickly as possible.

Options

Housing for the system

We offer a complete housing for your Odorization System. This is usually a stainless steel cabinet. We also provide special material housings.

Overfilling protection and leakage pan

Specially designed accessories: With a reliable overfill protection and leakage pans in different sizes, you get a clean and safe system.

Flushing system for easy cleaning

For easy and regular maintenance of the system, we recommend a flushing system for the pump, the piping and the tank for an odor-free disassembly and maintenance.

Design with safety valve

Designed for elavated suction pressures with pressure relief valve (0,5-3,0 bar).

Solenoid valve and pressure gauge

With a solenoid valve in the discharge line, you can control small gas flow rates (< 400 Nm3/h). A manometer for pressure pipes and tanks ensures the exact metering of the fluid.

Testing, acceptance and inspection

We make sure that everything works: LEWA offers numerous services, including factory acceptance test (FAT) at the manufacturing site or at your site (SAT), NDT and PMI.

Additional stand-by pumps

Efficiency and reliable operation of our systems are in focus: We provide additional stand-by pumps for easy system maintenance without downtime.

Suitable for all odorants

LEWA odorizing systems are suitable for all common odorants in the industry: EM, DMS, TBM, THT. Simply let us know your personal requirements.

Modular design

You are free to choose: Standard odorizing systems are designed to be highly modular and consist of various components which enables us to meet your requirements in a manner that is as flexible as possible.

Technical data

The LEWA metering systems have a modular structure. Various tanks, line systems, and pumps allow us to adapt every system to the requirements of our customers.

| System type | Tank size, max. [l] | Gas flow, max. [Nm3/h] | Gas pressure, max. [bar] with pump | Voltage [V] | Ex zone 1 | Control system | Container | |||

|---|---|---|---|---|---|---|---|---|---|---|

| MAH | MBH | MLM | LDB | |||||||

| OD7 | 50 | 10000 | 30 | 50 | 560 | - | 230 AC / 24 DC | √ | possible | standard/returnable |

| OD8 | 200 | 20000 - 70000 | 30 | 50 | 100 | - | 230 AC / 24 DC | √ | possible | standard/returnable non-returnable |

| OD60 - 1000 | 60 - 1000 | 10000 - 200000 | 30 | 50 | 100 | 170 | 230 AC / 24 DC | √ | possible | standard/returnable non-returnable for refilling |

Dimensions [mm]

| Type | H | W | D |

|---|---|---|---|

| OD7 | 1750 | 880 | 680 |

| OD8 | 2130 | 1700 | 850 |

| OD60 - 1000 | 2315 | 2005 | 1360 |

Industries

Gas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsDownloads

LEWA Dosier-und Mischanlagen - komplette Lösungen aus einer Hand. (DE)

In vielen verfahrenstechnischen Produktionsanlagen spielt das Dosieren und Mischen von Flüssigkeiten als Verfahrensschritt eine wichtige Rolle, der für die Qualität des Endproduktes mit verantwortlich ist.

4 MB

| pdf |

18.02.2022

LEWA metering and mixing systems-complete solutions from a single source. (EN)

In many manufacturing plants, the metering and mixing of liquids plays an important role as a

procedural step that ensures the quality of the end product.

4 MB

| pdf |

18.02.2022

LEWA Odorizing systems for natural gas, biogas and liquefied petroleum gas. (EN)

For more than 40 years, customers from all over the world have placed their trust in LEWA systems

for odorizing gas. Our portfolio ranges from systems for micro flow metering, such as biogas plants, to

gas pressure regulating stations.

3 MB

| pdf |

18.02.2022

LEWA Odoriersysteme für Erd, Bio-und Flüssiggas. (DE)

Seit mehr als 40 Jahren vertrauen Kunden aus der ganzen Welt bei der Odorierung von Gas auf Systeme von LEWA. Unser Portfolio reicht von Anlagen zur Kleinstmengendosierung,

wie z. B. bei Biogasanlagen, bis hin zu Gasdruckregelstationen.

3 MB

| pdf |

18.02.2022

Injection nozzle for odorizing systems from Böhmer (EN)

Injection nozzles for pipelines or ball valves in natural gas odorization

951 KB

| pdf |

17.05.2022

Impfdüse für Odoriersysteme von Böhmer (DE)

Impfdüsen für Rohrleitungen oder Kugelhähne in der Erdgasodorierung

1 MB

| pdf |

17.05.2022