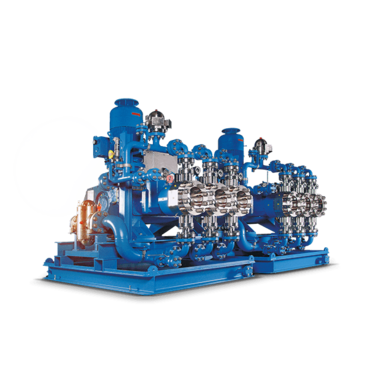

LEWA Pump Skids

The ready-to-operate solution for specific tasks.

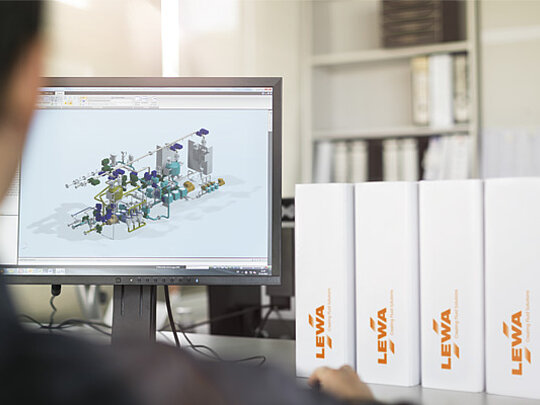

Do you need a turnkey pump skid or chemical injection skid? Look no further than LEWA. We offer a comprehensive service and complete project management: Our experienced engineers listen to your requirements and design the perfect skid for your application.

We don't leave anything to chance: We choose all the pumps, materials, and accessories for our pump skids. We guarantee the total function of the module, enabling us to provide a turnkey solution.

Our skids are designed according to specific requirements and the available space. And, of course, we take all national and international regulations into consideration. Our service covers everything from assembly, installation on frames, acceptance, and approval through to delivery, on-site installation, and commissioning.

Good reasons to choose a LEWA pump skid

A LEWA pump skid consists of a pump on a base plate with piping, accessories, and instrumentation.

Complete development from a single source

Pumps, accessories, design, and project management from a single source: We handle every stage of the project – from planning and construction right through to commissioning and subsequent maintenance. And our 60 years of industry experience make us a company you can trust.

Compliance with specific standards

All our pump skids are designed in accordance with national and international standards and regulations. And, of course, we stick to every customer-specific requirement. What's more, we take special regulations governing base plates and pipelines into consideration too – such as any associated welding and acceptance specifications.

Production sites all over the world

LEWA manufactures systems at various sites all over the world. As a result, we can provide spare parts and services wherever you are across the globe. This ensures that our pump skids are always obtainable – keeping your production work running. We guarantee long, continuous operating times as well as cost-effective, rapid maintenance on site.

Outstanding service around the clock

There for you when you need us: Our global commissioning and consultancy services are available 24/7. You'll have constant access to a qualified contact person who will take the time to give you expert advice on anything you need to know about.

Videos about LEWA pump skids

Options

Optimization of the efficiency

Especially for certain applications where only low electrical power is available, we will deliver efficiency-optimized pumps and motors.

Design calculation of the base plate

We provide designs for extreme acceleration forces, which is important for the base plate, as e.g. for the transshipment in the offshore sector.

Testing, acceptance and inspection

We make sure that everything works: LEWA offers numerous services, including factory acceptance test (FAT) at the manufacturing site or at your site (SAT), NDT and PMI.

Standard and special parts

LEWA offers standard or customized components for control and regulation. The integration into process control systems, also including process visualizations is possible.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

International standards

LEWA is ISO 9001 certified. Pumps, systems and units are compliant with all major international standards such as, API, ASME, TÜV and many more.

Compact design

We construct the Pump Skid space and weight-saving, if the skid has to be adapted to an existing installation where space is limited or the maximum total weight is nearly achieved.

Complete documentation

In the process of documentation, we consider your requirements and provide inspection records, print samples, diagrams of output characteristics and registration papers on request.

Maintenance and service

No matter if maintenance, spare parts or repair - our service technicians are well trained and available worldwide. Thus, we guarantee fast response and smooth operations.

Technical data

Our pump skids are designed for a range of applications. Thanks to the wide range of pumps, materials, drives, and pipeline systems we provide, we can ensure maximum flexibility.

Adjustable flow rates and discharge pressures

Our pump skids are suitable for flow rates up to 180 m3/h. With plunger pumps, you can achieve discharge pressure levels of up to 3500 bar; with diaphragm pumps, up to 1200 bar.

Pumps used compliant with API standards

The metering pumps used on our pump skids are all API 675-compliant and our plunger pumps all meet API 674 standards. Each of the two pump types is available in a single-pump head or multiple-pump head configuration.

Various materials

We manufacture pump skids from various materials to suit the application type. These materials include stainless steels of different kinds, high-alloy steel and nickel compounds, plastics, as well as special materials for specific purposes.

Various drive types

No matter which energy source you want to use to power your pump skid, we can provide you with the right drive for the job. Anything is possible – from electric, pneumatic, and hydraulic drives through to diesel units and solar-powered motors.

Flexible pipeline systems

The pump skid pipeline system needs to be precisely adapted to the specific intended use of the system. We offer systems in accordance with DIN/EN, the BASF (IG) high pressure standard, dairy pipe fittings, ANSI, Ermeto, Graylock, Swagelok, and plastic lines. And, of course, we adapt the skid to your specific pipeline system.

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsApplications

Injection of corrosion inhibitor

Do you require systems for the injection of corrosion inhibitor? At LEWA, you can find expert consultation, detailed information and support!

More DetailsMethanol injection

Use skids and packages by LEWA for methanol injection in the oil and gas industry. Ask our experts for more information!

More DetailsCCS carbon capture and storage

Use LEWA process pumps for CCS (carbon capture & storage) processes and carry out the CO2 separation efficiently. We are happy to help.

More DetailsGas drying with glycol

LEWA provides reliable injection pumps and systems for gas drying with glycol. Ask our experts for more information today.

More DetailsInjection of demulsifiers

Injection of demulsifiers with LEWA packages in the oil and gas industry. We provide you with advice tailored to your application.

More DetailsMetering of silane

LEWA systems meter any silane type reliably, precisely as well as in constant consistency and purity, regardless of chemical or physical attributes or process requirements.

More DetailsFlue gas cleaning by means of metering sulfur | LEWA

When using an electrofilter for flue gas cleaning, metering sulfur improves the filtration efficiency. LEWA has the solution!

More DetailsSulfuric acid injection in copper heap leaching

LEWA process pumps are used to reinject sulfuric acid at 98% into the main pipelines that go to the heap leach sprinklers.

More DetailsDispersing

With the diaphragm metering pumps and streamlined suspension valves, LEWA offers the suitable solution for the metering of fluids with solid particles.

More DetailsAdditive dosing for fuels

LEWA supplies both diaphragm metering pumps and process diaphragm pumps for additive dosing in fuels. We provide you with the right pump and advice for your application.

More DetailsPolymerization in EVA reactors with process pumps

Production of ethylene vinyl acetate (EVA) with LEWA process pumps. We provide you with the right pump and advice for your application.

More DetailsDownloads

LEWA Lösungen für die Öl- & Gasindustrie. (DE)

High-end Dosier- und Prozesspumpen sowie Systeme und Packages für spezifische Funktionalitäten zum Einsatz in der On- und offshore Förderung.

4 MB

| pdf |

18.10.2022

LEWA Solutions for the Oil & Gas Industry. (EN)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

18.10.2022

LEWA Dosier-und Mischanlagen - komplette Lösungen aus einer Hand. (DE)

In vielen verfahrenstechnischen Produktionsanlagen spielt das Dosieren und Mischen von Flüssigkeiten als Verfahrensschritt eine wichtige Rolle, der für die Qualität des Endproduktes mit verantwortlich ist.

4 MB

| pdf |

18.02.2022

LEWA metering and mixing systems-complete solutions from a single source. (EN)

In many manufacturing plants, the metering and mixing of liquids plays an important role as a

procedural step that ensures the quality of the end product.

4 MB

| pdf |

18.02.2022

Soluciones de LEWA para la industria del petróleo y gas. (ES-SA)

Bombas de dosificación y de proceso de alto nivel, así como sistemas y paquetes para funciones específicas para su uso en producción tanto en la tierra como en el mar.

3 MB

| pdf |

18.02.2022

LEWA Solutions for the Oil & Gas Industry. (USA)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

06.11.2022