Solutions for the production of caustic soda and other bases

Advantages of LEWA systems in dilution of caustic soda and other bases:

- Suitable for all concentrations

- Enables simplified processes

- Process of caustic dilution works both in manual operation as well as in automatic operation

- Dual analysis system – for process control, concentration test and recording of the process

- Optional temperature monitoring to avoid precipitation

- More flexibility in production

- More independence from supplier quantities

- Stocking small amounts is possible or storage times are increased

- Cost savings in caustic dilution and logistics

Areas of application for LEWA systems for caustic dilution

Applications, in which the LEWA inline caustic dilution system can be used:

- Water treatment

- Food processing (e.g., rinsing and cleaning bottles in drink filling systems, removing greasy and oily contamination)

- Production of cleaning agents (e.g., of sodium soaps)

- Vegetable oil processing

- Processes in the chemical industry (e.g., neutralizing acids)

- Cleaning pharmaceutical facilities with CIP in varying concentration

- Glass processing

Background for the production of caustic soda and other bases

Process description of caustic dilution:

Caustic solutions, such as caustic soda, are normally commercially available in concentrations of 50% and higher. The dilution of an alkaline solution is a controlled process, which prevents precipitation and/or extreme exothermic reactions.

Caustic soda is the designation for solutions of sodium hydroxide (NaOH) in water. These are alkaline solutions. Caustic soda dissolves very well under heat development in water. Caustic soda is one of the most frequently used laboratory and industrial chemicals as a cleaning agent.

Industries

Chemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

LEWA ecoflow® diaphragm metering pump

LEWA ecoflow is the innovative and universal metering pump with DPS diaphragm protection system in a tried-and-tested modular system. Suitable for numerous applications, the ecoflow is our real all-around talent, relied on by customers from all industries.

More DetailsLEWA ecodos® mechanical diaphragm metering pump

LEWA ecodos is an absolutely reliable, economical and highly adaptable metering pump, especially where diaphragm actuation is not wanted. Here, we also rely on our tried-and-tested modular system in designing the perfect pump for you.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

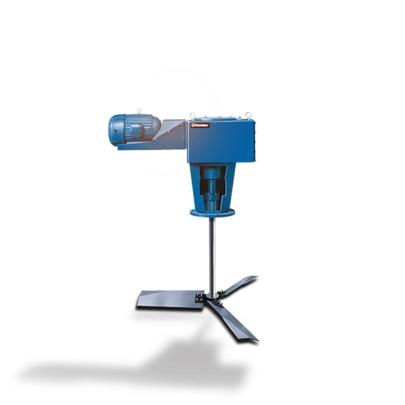

More DetailsChemineer Mixing technology

Chemineer agitators cover a wide range of products. From turbine agitators to impellers, these agitators can be used in almost any process that requires liquid or gas agitation.

More Details