Solutions

Advantages of LEWA diaphragm process pumps in supercritical fractionation:

- Almost linear pressure-resistant pump characteristic ensures constant pressure in the separation columns (e.g. SFC)

- Gradient elution possible

- When solvents are added to the mobile phase of CO2, an ATEX (explosion-proof) diaphragm pump version can also be offered

- Hermetically tight (no microbial contamination or leaks) and permanently safe with CO2

- Hygienic design especially suitable for food and pharmaceutical processe

- Alternative materials for corrosive fluids possible (e.g. Hastelloy)

- Fulfillment of necessary international standards and regulations for production in regulated industries (GMP)

Background

One solvent – two methods

In extract production with CO2, a combination with supercritical extraction (SFE) and high-pressure fractionation for example by supercritical chromatography (SFC) is sometimes used.

When fractionating certain ingredients, the reactive surface area has to be increased. In the SFC process with supercritical CO2, the extract obtained from the previous extraction is thus passed through a high-pressure column. This is filled with a finely structured chromatography medium. It ensures that the extract is divided again–into the fractions. For example, the omega-3 fatty acids DHA or DPA can be obtained from fish oil fractions. This process is shifted both in time and in terms of size. Concentrates of the highest purity can be obtained from the purified fractions.

In order to protect sensitive natural products from harmful oxidation, temperature influences or other adverse effects, CO2 is used as a solvent

CO2 is environmentally friendly in comparison to conventional solvents and achieves an extremely high degree of purification. In addition, it is reusable and therefore beneficial for maintenance. This also helps justify the investment costs of high-pressure fluid technology and integrated diaphragm pumps.

In the pharmaceutical sector, the extraction and purification process is used in the extraction of cannabinoids, for example. Cannabinoids, terpenes and other substances are dissolved from cannabis plant material (hemp). The recovered cannabis extracts contain cannabinoids tetrahydrocannabinol (THC) and cannabidiol (CBD), which are of interest for pharmaceutical use.

Industries

Chemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsProducts

LEWA ecoflow® diaphragm metering pump

LEWA ecoflow is the innovative and universal metering pump with DPS diaphragm protection system in a tried-and-tested modular system. Suitable for numerous applications, the ecoflow is our real all-around talent, relied on by customers from all industries.

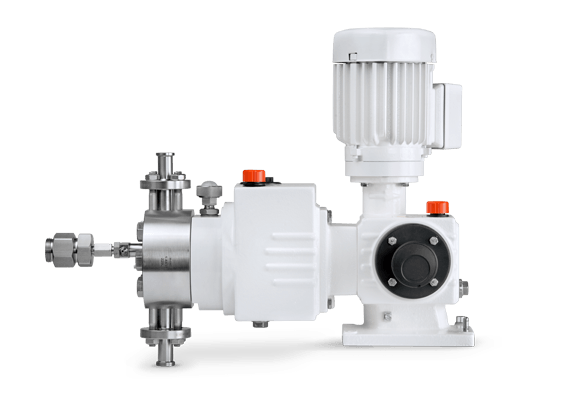

More DetailsLEWA ecoflow® sanitary/hygienic diaphragm metering pump

LEWA ecoflow is also available in sanitary/hygienic. The metering pump for hygienic applications has the same all-around capabilities and fulfills all specifications for pharmaceutical and food production.

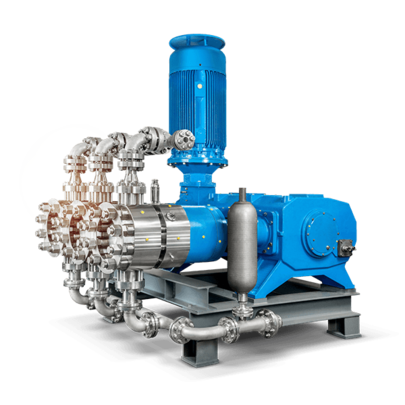

More DetailsLEWA triplex® process pumps for high-pressure processes

The LEWA triplex process diaphragm pump is among the world's most compact high-pressure pumps and can even be set up in the tightest spaces when space is at a premium. The power package has proven its strength in numerous high-pressure processes in a variety of industries. Oil and Gas icon Gas odor icon gray Refinery icon Petrochemicals icon Chemicals icon Plastics icon gray Cleaning icon Cosmetics icon Pharma icon Food icon Energy icon Other icon

More Details