Aseptic solutions for metering sensitive fluids

LEWA hygienic metering pumps are hermetically sealed, leak-free, and have no connection to the product chamber. This ensures contamination-free metering and conveying.

Advantages of hygienic metering pumps:

- Liquid end hermetically tight, 4-layer safety diaphragm with leakage detection

- Superior priming, low shear and wear

- CIP/SIP up to 150°C

- Aseptic design according to EHEDG

- Compact servomotor without fan (cleanroom)

- 316L or higher (e.g. hastelloy) and plastic

- Continuous operation possible

- ATEX design possible

- Qualified in the OEM pharmaceutical sector worldwide for decades

References of LEWA pumps for pharma applications

Industry: Pharma API

Application: Oligonucleotides DNA/RNA synthesis; highly toxic and flammable fluids up to 10 bar

LEWA Solution:

- Hermetically tight diaphragm metering pump in sanitary design

- CIP/SIP possible

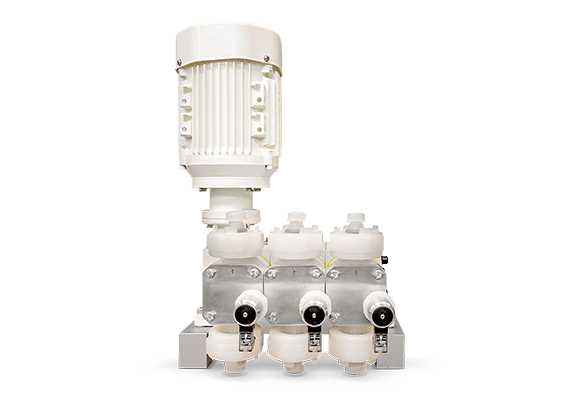

- Multiplex design

- Compact motor for clean environment

Industry: Biopharma

Application: Conveying aqueous buffers, WFI and monoclonal antibodies at various flow rates (linear, step or gradient) at a pressure of up to 6 bar max.

LEWA solution:

- Hermetically tight diaphragm metering pump for chromatography, inline dilution processes among others

- CIP possible

- Corrosive resistant polypropylene or PEEK pump heads (no metal in fluid path)

- Multiplex design

Areas of application

Relevant areas of applications

- Biopharma (downstream purification)

- Pharma (API/vaccines/oligos)

- Media preparation (buffer Inline-dilution)

- Utilities (NaOH, WFI; solvents; CIP)

Background

Background information for sterile applications

GMP stands for "Good Manufacturing Practice" for Medicines. For example, the GMP rules lay down requirements for hygiene, premises, equipment, documentation and controls.

The production of sterile products, such as pharmaceuticals, therefore has special requirements in order to minimize the risk of contamination with microorganisms, particles and pyrogens. Quality assurance is of particular importance in this context. Production must be carried out strictly according to defined and validated methods and procedures.

The metering pumps used are an important component of the production facilities. Therefore, they must also meet the GMP requirements. Important properties include CIP/SIP cleanability or hermetic tightness.

Industries

Pumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsProducts

LEWA ecoflow® sanitary/hygienic diaphragm metering pump

LEWA ecoflow is also available in sanitary/hygienic. The metering pump for hygienic applications has the same all-around capabilities and fulfills all specifications for pharmaceutical and food production.

More DetailsLEWA ecodos® sanitary/hygienic diaphragm metering pump

A sanitary/hygienic version is also available for the LEWA ecodos. Here, we meet all requirements for operation in pharmaceutical and food production.

More DetailsDownloads

Diaphragm metering pumps for sterile applications (EN)

Diaphragm metering pumps for sterile applications in the pharmaceutical industry (GMP).

332 KB

| pdf |

18.02.2022